You want longer running machines. Period. Still, regardless of what you do, you too often come up short. Why? Most companies start a vibration program by buying new instruments and instrument training. Their maintenance strategy is a monitoring scheme that “picks out the bad from the good.” But too little emphasis is given to preventing problems from occurring in the first place. Monitoring and occasional analysis alone will never produce the tremendous results of a true MIP.

Additionally, most Plant and Maintenance Managers are faced with maintaining the same number of machines, with less people than in the past, often with early retirement eliminating some of their most experienced, knowledgeable help. They are further pressured with less time and financial resources.

The greatest payback is achieved not only by determining when machines are going bad, but improving and increasing the life of all equipment – the good and the bad – when worked on for any reason.

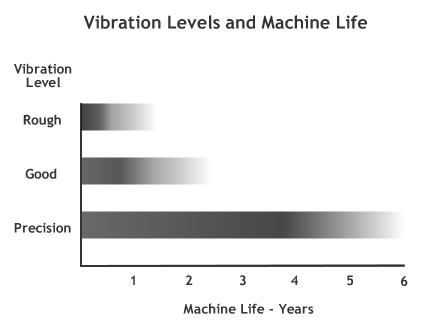

The best, most reliable results come from taking a proactive stance. Update’s comprehensive, practical training focuses on prevention through precision performance. When machines run at precision vibration levels, machine life increases exponentially.